Montreal Plant

400 George V, Lachine, QC, H8S 2R7

Hot-dip galvanizing is a sustainable process which enables you to enhance the durability of your steel, regardless of its shape or size, making it maintenance-free for decades.

• Galvanizing is the sustainable solution preferred by Architects and Engineers.

• Galvanizing offers the most durable method of corrosion protection for steel and rebars.

• Galvanized coatings offer the optimal solution to reduce maintenance operations for over 100years.

• Galvanized coatings eliminate the premature replacement of steel products.

• Galvanizing is a key contributor to the reduction of the whole life carbon footprint of a structure and components by reducing the embodied carbon of construction.

• Galvanization combines highly recyclable steel and zinc into a durable alloy, aligned with global targets in achieving a circular economy by preserving raw materials as valuable assets.

• Hot-dip galvanization does not require the use of chemicals that are harmful to the environment, reducing the carbon footprint.

.webp)

%20(1).webp)

You decided on steel: excellent choice! Steel is a material known for its strength and versatility, but upon galvanization it becomes even more stronger and durable. With a long-lasting maintenance-free finish, enjoy the benefits of galvanized steel for decades, all while keeping costs and sustainability in mind. Trust Corbec for all your galvanizing needs.

.webp)

.webp)

%20(1).jpg)

%20(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

From shipped to galvanized in the shortest timeframe, with scientific precision, and open communication.

All steel that arrives at our plants is subject to a thorough inspection for proper drainage, venting and hooking requirements.

In this critical step, your steel is thoroughly cleaned and rinsed in different stages to remove contaminants and ensure the zinc will react with ever part of the surface, resulting in a uniform layer that maximizes protection and durability.

There are 3 steps in the Surface preparation process.

The steel is submerged in a bath of molten zinc until it reaches 450° C (840° F). At this point, the zinc reacts with the steel to form zinc/iron intermetallic layers on all surfaces, inside and out. Unlike paint, which is a surface coating, the zinc forms a lasting chemical bond with the steel.

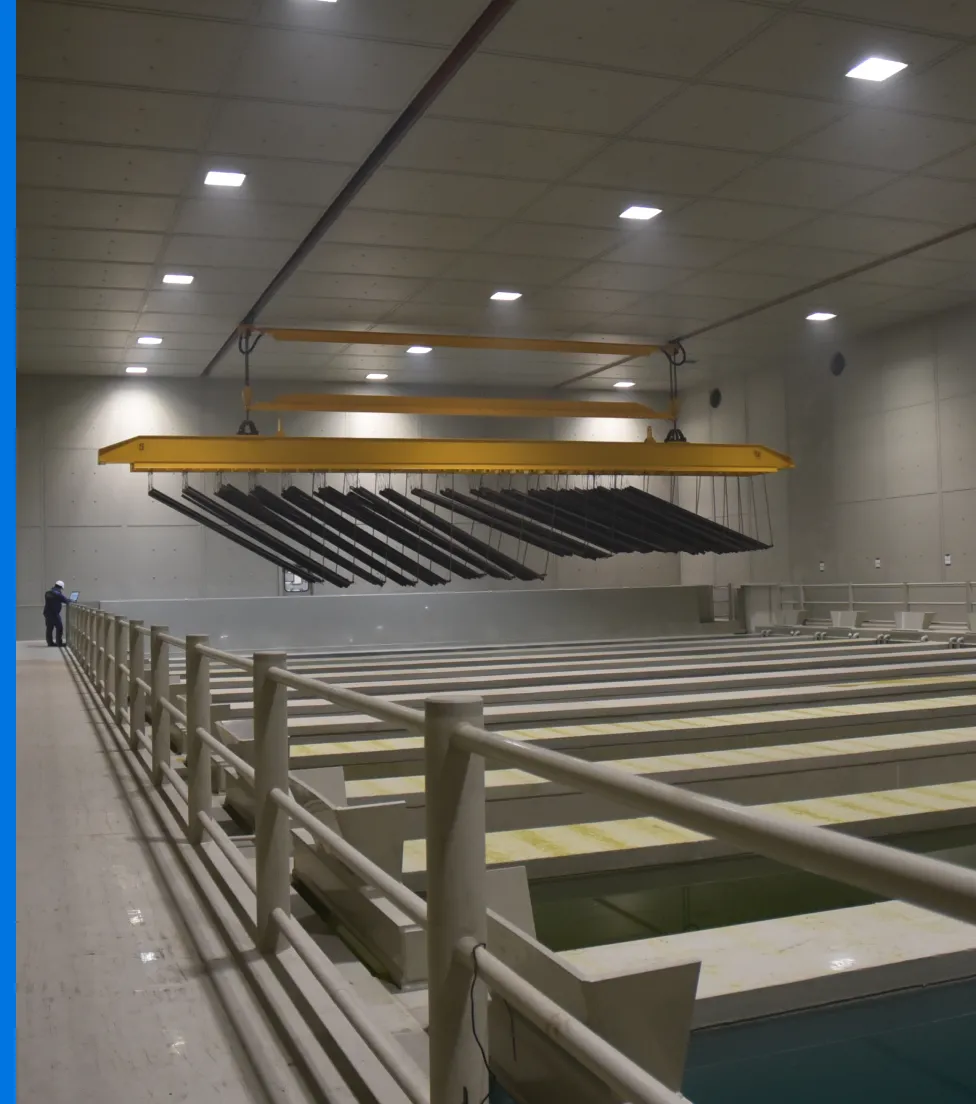

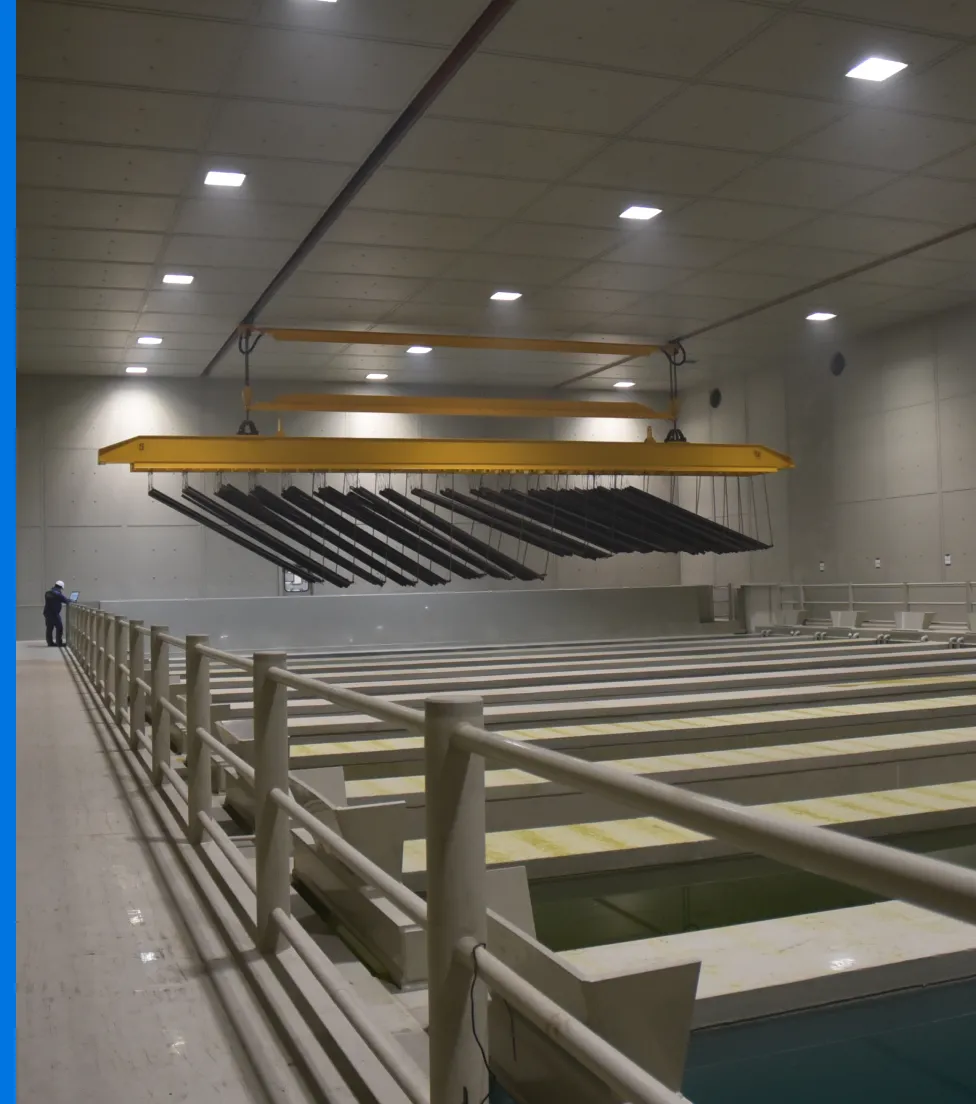

Optimally located, and equipped with Canada’s largest kettles, our facilities are perfectly positioned to deliver galvanized steel at scale.

Here’s what you can expect when working with us – from choosing the perfect materials to preparing your galvanized steel for the next stages.

Each project is scoped to produce the optimal selection of materials and techniques to meet your requirements for corrosion protection, coating thickness and aesthetics.

The composition of your steel impacts the performance of the galvanized coating and, therefore, material selection. The levels of four basic elements are considered: carbon, silicon, phosphorous and manganese.

In the preliminary design stage, we help our customers identify requirements, establish objectives, and consider potential issues during the galvanizing process. Our team takes extra care in ensuring clear, open communication.

Various thicknesses of bolted and welded assemblies can deform or distort due to heating and cooling of the parts. When significant distortion risk is present, our team will recommend galvanizing before assembly.

Many customers paint steel after galvanization to improve aesthetics and increase service life (by 1.5 to 2.5 times in duplex-painted systems). We can prepare the steel surface for painting with an oxidation (or “aging”) process.

.webp)

.webp)

.webp)

.webp)

Corbec complies with the industry’s most stringent quality and sustainability protection standards, including ASTM International (formerly, American Society for Testing and Materials) and CSA (Canadian Standards Association).

We are also members of prominent industry organizations in Canada and beyond.

Scope your project and know exactly what to expect, with personalized attention by our experts.

For general inquiries, partnership options, or anything on your mind. Let’s talk shop!