Zinc is a natural and abundantly available element that has been used in construction for millennia. Zinc metal has a number of characteristics that make it a well-suited corrosion protective coating for iron and steel products.

Steel has to be wisely selected for optimal coating. The following information is based on ASTM A-385. The relative corrosion resistance of an aesthetically normal or abnormal coating is, all in all, equal.

The quality and durability of galvanized coatings depend, among other things, on the correct selection of steel based on its physical and chemical properties, and on compliance with design and assembly standards for structures intended to be galvanized. Our customer service team will be delighted to help you with your galvanizing projects.

.jpg)

Carbon, silica, phosphorus and manganese are the main elements to consider when selecting steel for a project involving hot-dip galvanizing. The concentration ranges in which these elements must be found are well defined in the ASTM A385 standard. Respecting these selection parameters will ensure that the zinc coating obtained during the galvanizing process will offer effective, resistant and durable protection during the useful life of the galvanized part.

Some steels, such as high strength steels, may be subject to embrittlement during galvanizing. Although not very frequent, it is important to consider the recommendations of the ASTM A143 standard when selecting the steel in order to minimize the risks related to embrittlement. It's challenging to provide exact guidance on steel selection without knowing the commercially available steel grades. There are 4 basic elements to consider as they are shown to affect the galvanized coating.

%20(1).jpg)

%20(1).jpg)

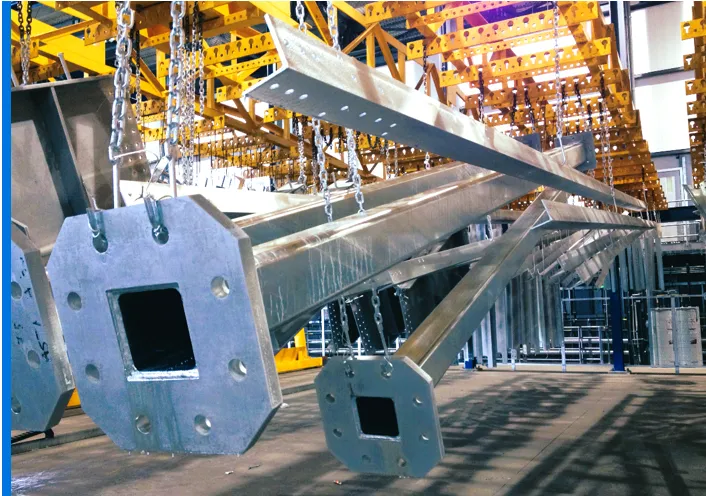

The hot-dip galvanizing process involves the complete immersion of steel parts and structures in a pool of molten zinc. As a result, the design of assemblies intended for galvanizing differs significantly from that of structures and assemblies that are painted.

In order for a part to be galvanized, it must have the capacity to be racked onto a beam - something that should be considered during the design phase. In addition, the design of steel structures and assemblies with ventilation and drip holes that meet ASTM A385 criteria is critical for safe immersion in the kettle and for quality galvanizing.

VENT HOLES:

The primary purpose of these holes is to allow air to be evacuated from within and around the part, while the secondary purpose is to prevent pressure buildup and localized uncoated surfaces caused by trapped moisture or cleaning solutions. Vent holes should be located at the highest point and drain holes at the lowest point to ensure proper coating coverage and avoid unwanted explosions!

DRAINING HOLES:

To ensure effective galvanizing, it is important to provide free and unimpeded flow of cleaning solutions and molten zinc through the part. Poor drainage design can lead to complications and poor coating quality. It is important to follow best design practices for drainage in common fabrications such as gusset plates, stiffeners, end-plates, and bracing. Holes should be placed in cropped corners or as close to corners as possible, and stiffeners, gussets, and bracing should be cropped a minimum of 3/4 inches. End-plates should have holes at least 1/2 inches in diameter placed as close to interior corners as possible or in the web within 1/4 inches of the end-plate.

Chart 1. - Drainage holes for overlapping surfaces - steel thickness less than or equal to 1/2" (1.25 cm)

Some applications require the assembly of steel parts of different sizes and thicknesses, while others require large quantities of welds, creating many residual thermal constraints in the assembly.

In such cases, the application of the recommendations stated in the ASTM A384 standard makes it possible to orient the design and fabrication in such a way as to minimize the risks of deformation and distortion that would occur during the galvanization process. A design that respects the spirit of the ASTM A384 standard combined with the know-how and expertise of the galvanizer are the key ingredients to the recipe of success for flawlessly galvanized product.

%20(1).jpg)

%20(1).jpg)

Although the look that galvanizing confers on steel structures is highly prized, it is also possible to paint galvanized steel.

The development of duplex systems combining hot-dip galvanizing and painting, or hot-dip galvanizing and electrodeposition powder coating, opens the way to the use of galvanized steel in a multitude of applications ranging from architectural aesthetics to extending the life of galvanic protection in certain hostile and corrosive environments.

The ASTM D6386 and D7803 standards cover the key elements required for the development of durable, high-performance duplex systems.

%20(1).jpg)

%20(1).jpg)

The following is a list of questions commonly asked by our clients. Please contact us if you have a question about our process that is not answered below.

Zinc is a natural and abundantly available element that has been used in construction for millennia. Zinc metal has a number of characteristics that make it a well-suited corrosion protective coating for iron and steel products.

Yes. Coating steel with zinc through the hot-dip galvanizing process protects it from corrosion, with minimal environmental, economic and social impacts. Not only does hot-dip galvanizing provide decades of maintenance-free longevity, but its primary components, zinc and steel, are natural, abundant, and 100% recyclable, making hot-dip galvanized steel an infinitely renewable building material.

Depending on the product mix, square feet per ton, and condition of the steel surface, galvanizing is often less expensive on an initial cost basis. However, as with any purchase, the lifetime costs should be considered when making a project decision on the corrosion prevention system to utilize. And, with galvanizing, the life-cycle cost, i.e. the cost per year to maintain, is almost always less than a paint system. Paint systems require maintenance, partial repainting, and full repainting several times over a 30-year project life. The costs can be staggering, making the decision to paint a costly one in the long run.

Yes. Corbec uses standards and processes that meet the specifications for hot-dip galvanizing issued by the Canadian Standards Association (CSA) and the American Society for Testing and Materials (ASTM). The test results and certificates of compliance for selected specifications are also available, provided the request is made on the original order, delivered before galvanizing.

There are limits to the size of piece that can be accommodated in our kettles, however, it is best to contact us and we can discuss options and solutions. Double-dipping is a progressive immersion procedure for parts that are too large for in a single dip in the kettle. This procedure cannot be used to obtain additional coating.

The chemical composition of the steel used largely determines the final appearance of the galvanized product and the thickness of the coating. Steels produced by foundries have a wide range of compositions, and consequently, the galvanizing results differ.

Best practice suggests steel to be galvanized should be symmetrical and of similar thickness. When this is not possible, it is best to consult with the galvanizer. The guidelines for safeguarding against warping and distortion during hot-dip galvanizing of steel assemblies are outlined in ASTM A384

This term is often used incorrectly instead of the more common term "wet storage stain", which is a slight corrosion and much less serious than white rust. Storage stains can be avoided by storing freshly galvanized steel according to guidelines, avoiding exposing unprotected surfaces to moisture or water, or by applying a surface passivation treatment. These spots will disappear once the galvanized steel is exposed.

The ventilation holes are required to enable the full flow of liquid when cleaning and during galvanization. Since the material must be fully protected, zinc must circulate freely in all cavities of a part or structure.

Yes. Painting done according to standards will extend the service life of galvanized materials.

No. The chemical composition of the steel and the condition of the surface will determine the thickness of the zinc coating. An increase in the thickness of the coating will only weaken the top layer of zinc and may result in flaking.

%20(1).jpg)

%20(1).jpg)

Our commitment lies in sharing our knowledge. We firmly believe that informed decisions drive better results. Reach out to us today and let our experience and expertise work to your advantage.